Protecting the future

Protecting the future

Protecting the future

Protecting the future

Protecting the future

Protecting the future

Protecting the future

8th March 2024

In the ongoing battle against corrosion, the pursuit to extend the lifespan of assets has led to a consideration of corrosion prevention rather than just protection. Concerns regarding coating performance often lead to disputes over responsibility, involving manufacturers, contractors, and project timelines, potentially compromising quality. However, when analyzing the suitability of a coating system, the selection of visco-elastic coating to not only perform in the right conditions but also be able to be applied in difficult in-field conditions must be considered during the design and selection phase. Advancements in coating technologies, particularly those incorporating coatings commonly known as visco-elastic coating, are proving efficient and safer to apply coatings while reducing the need for maintenance over the lifetime of an asset.

Conventional Coating Systems

The conventional method of corrosion prevention involves creating a barrier over the material surface to shield it from the environment. Traditionally, liquid coatings such as epoxies and paints are frequently used to coat many different above and below-ground assets. However, these coatings often need to bond to a substrate with a specific surface profile creation through abrasive blasting, and thus, require stringent surface preparation and application QA/QC before, during and post application. Within a practical application environment, for any type of coating technology, the wetting phase is crucial for achieving adhesion. For liquid coatings to achieve good adhesion, they need both a clean surface and an optimal surface anchor profile. The anchor profile allows for the increase in total surface area and allows for mechanical bonding of the liquid coating within the peaks and valleys of the profile. With respect to industry standards, a near-white metal finish (SSPC-SP 10 or Sa 2 ½) is required to have a rust and debris-free substrate, while creating a sufficient profile sufficient for the liquid coating to penetrate and create a strong bond with the substrate.

Easy Solutions for a Challenging Application Process

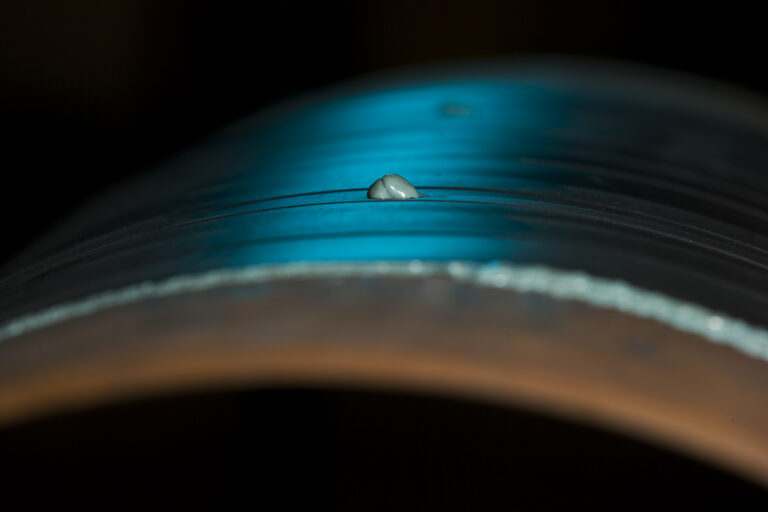

With surface preparation being a key factor to the overall success of a coating, there would be a benefit to both contractors and end-users to specify and apply technology which is effective without the need for a long surface preparation and application checklist. Coating technology known in the coatings industry as visco-elastic coating, and more specifically polyisobutene (PIB) based coatings, does not age or degrade and stays in a viscous state throughout its lifetime. A design feature of the coating system through the use of this coating technology is the inherent nature of the compound being non-curing, non-crystalline, and a fully amorphous low-viscosity material (ISO, 2016). The non-crosslinkable, liquid-like polymer with a low glass transition temperature offer key advantage, mainly in its ability to provide immediate and constant wetting of the surface, forming an instant barrier that blocks oxygen and water, thereby preventing corrosion. The non-crystalline nature, with a glass transition temperature below -60˚C (-76˚F), ensures that the corrosion protection adhesive compound maintains its fluid-like nature of wetting the surface at all times. This includes any movement with thermal expansion or contractions, pressure expansions and contractions, asset vibrations and movements.

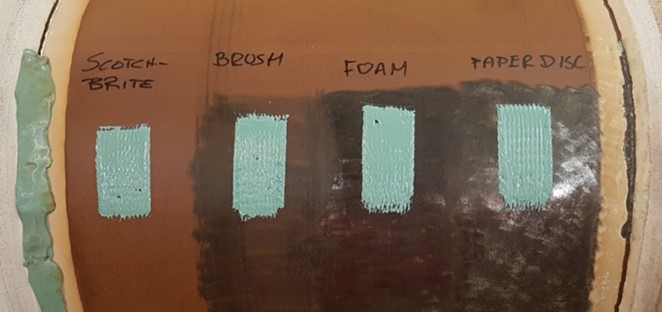

Products like STOPAQ visco-elastic coating, with their viscous phase, penetrate surface pores almost instantly and effectively, ensuring lasting adhesion. The visco-elastic coating products offer compatibility to various substrates, often demonstrated with adhesion on steel, polyethene, polypropylene, and coal tar enamel, resulting in cohesive fractures which always leave a protective compound on the substrate, ensuring the coating’s robustness and longevity. In fact, the surface preparation requirements only require the removal of loose existing coating (if any), the removal of larger debris particles and oil or grease on the substrate. If applied to a metal substrate, the surface only requires to have a minimum hand tool cleaning SSPC-SP2 (St. 2) or power tool cleaning SSPC-SP3 (St. 3) finish. The reduction of stringent surface profile requirements also leads to the reduction of inspection points and steps required to achieve the necessary cleanliness and restrictions for the success of traditional coatings. The additional benefits of using simple tools for surface preparation include; reduction of work space, access to hard-to-reach places, reduction in need for complex and specific abrasive blasting equipment or media, reduction in energy requirements, reduction of waste, and no shutdown requirements or loss in productivity.

The Practical Approach

The table below compares both the surface preparation requirements and typical application QA/QC checkpoints of applying traditional liquid coatings and a typical Stopaq coating system.

| Surface Preparation Checklist | Traditional Liquid Coatings | STOPAQ Coatings |

| Surface shall be dry and free of any contamination (such as detritus, dust, non-adhering particles, grease, oil, soluble salts) | Remove loose existing coating if any, debris and dust | Remove loose existing coating if any, debris and dust |

| Oil, grease and wax shall be removed by solvent cleaning in accordance with SSPC-SP1. | Clean per SSPC-SP1 | Clean per SSPC-SP1 |

| All visible surface imperfections, such as welding slag and spatter, etc. shall be removed | Fully Applicable | N/A |

| Areas of rust or scaling shall be removed by spot abrasive blast-cleaning or wire brushing | Loose rust requires spot abrasive blasting | Loose rust requires wire brush cleaning |

| Abrasives media used (ISO 11124 or ISO 11126) | Fully Applicable | N/A |

| Compressed air for blast-cleaning shall be free of oil, condensed moisture and any other contaminants | Fully Applicable | N/A |

| Reclaimed abrasive blast materials shall not be used unless automatic reclaiming equipment is used. | Fully Applicable | N/A |

| The profile/roughness check in (ISO 8503‑5). In areas where the roughness of the profile does not meet these requirements, the surface shall be reblasted. | Fully Applicable | N/A |

| Soluble salts shall be ≤20 mg/m2 (ISO 8502‑6 or ISO 8502‑9) | Fully Applicable | N/A |

| If wire-brush cleaning is permissible it shall be to St 2 wire brush or St 3 power tool cleaning (ISO 8501-1/3) | Cannot wire brush or power tool clean, requires abrasive blasting and Sa 2 ½ surface preparation (near white) | Min St 2 wire brush cleaning required |

| Peak profile density | Fully Applicable | N/A |

| Abrasive blasting pressure | Fully Applicable | N/A |

| Dust contamination (ISO 8502‑3) | Fully Applicable | N/A |

| The temperature of the substrate shall be at least 3 °C above the dew point. | Fully Applicable | Applicable to some products STOPAQ WSH can be applied on a wet substrate. |

| No Flash Rust | Fully Applicable | N/A – can withstand small amount of rust and flash rust |

| Application QA/QC | ||

| Specific ambient and substrate temperature range | Fully Applicable- Often times above 0oC and within a max temperature range | Highly Recommended- temperature range of -45oC to +120oC. |

| The applied coating shall be free of anomalies (grit, foreign particles, fish eyes, blisters, etc.) | Fully Applicable | Recommended |

| Adherence to mixing ratio (if multi-component coatings) | Fully Applicable | N/A |

| Mixing Times (if multi-component coatings) | Fully Applicable | N/A |

| Spray equipment nozzle type (if spray applied) | Fully Applicable- if spray applied | N/A |

| Spray equipment spray pressure (if spray applied) | Fully Applicable- if spray applied | N/A |

| Cure Times | Fully Applicable | N/A |

| Recoat Time | Fully Applicable | N/A |

| Wet Film Thickness (WFT)measurement | Fully Applicable | N/A |

| Dry Film Thickness (DFT) measurement | Fully Applicable | Recommended |

| Holiday detection test | Fully Applicable | Highly Recommended |

| Shore hardness | ||

| Adhesion to steel surface and plant coating at ambient temperature | Fully Applicable- Often times destructive testing required and need for repairs | Highly Recommended- done non-destructively by checking adhesion to surface prior to full coating |

| Repair of Adhesion tests | Fully Applicable | N/A |

Sustainable Benefits and Emission Reduction

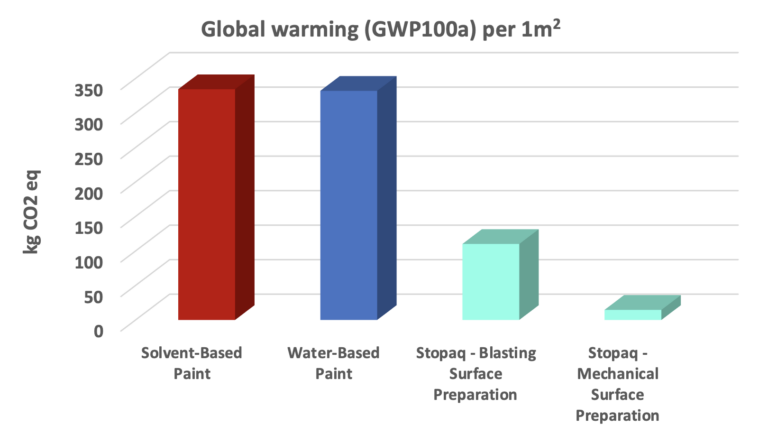

Life Cycle Impact Analysis of solvent-based paint, water-based paint, STOPAQ applied with blasting surface preparation, STOPAQ applied with mechanical surface preparation for a lifetime of 25 years for an offshore infrastructure shows a significant environmental performance improvement, human health improvement, and resource gain for Stopaq coating.

Over the lifetime of 25-year, the STOPAQ applied with mechanical surface preparation in comparison with solvent-base paint system shows:

- 96% reduction in overall carbon emission. The carbon emission reduction is equal to annual CO2 offsetting by 16 trees per m2 of the coating

- 98% reduction in carbon emission in end-of-life process

- 96% reduction bulk waste and 90% reduction in hazardous waste per m2

- 91% reduction in single score impact (ecosystem, human health, resources)

Conclusion

STOPAQ reduces risk of coating failures and extends the lifetime of assets by eliminating stringent requirements of surface preparation including abrasive blasting, only requiring SSPC-SP2/3 (St.2/St.3) surface preparation, while reducing complexity during application. Additional benefits as a result of having flexibility and versatility in application, include having the ability to tackle dynamic variables in challenging application areas, having the ability to coat without the need for shutdown, and complex equipment. STOPAQ’s surface preparation and application steps, combine with STOPAQ’s proven, successful track record of over 20+ years becomes an important part of the build design before it gets to a critical point. By using STOPAQ there are significant waste and emission reductions, having the potential to reduce overall emissions and waste typically seen from application and maintenance of traditional coatings system by 96%.

As industries evolve, embracing innovative technologies becomes imperative to ensure the longevity and integrity of vital infrastructure.

References

ISO. (2016). ISO 21809-3 Petroleum and natural gas industries — External coatings for buried or submerged pipelines used in pipeline transportation systems. ISO.