Pipeline tape technology

Polyken

Cold-applied and Heat-fused tapes

Product RangeAbout Polyken

A range of tape coating systems that can be plant- or field-applied to meet current global standards.

Polyken coating systems consist of polyethylene films laminated with butyl-elastomeric adhesives with an in-service performance from -20 ̊C to 85 ̊C (-5 ̊F to 185 ̊F).

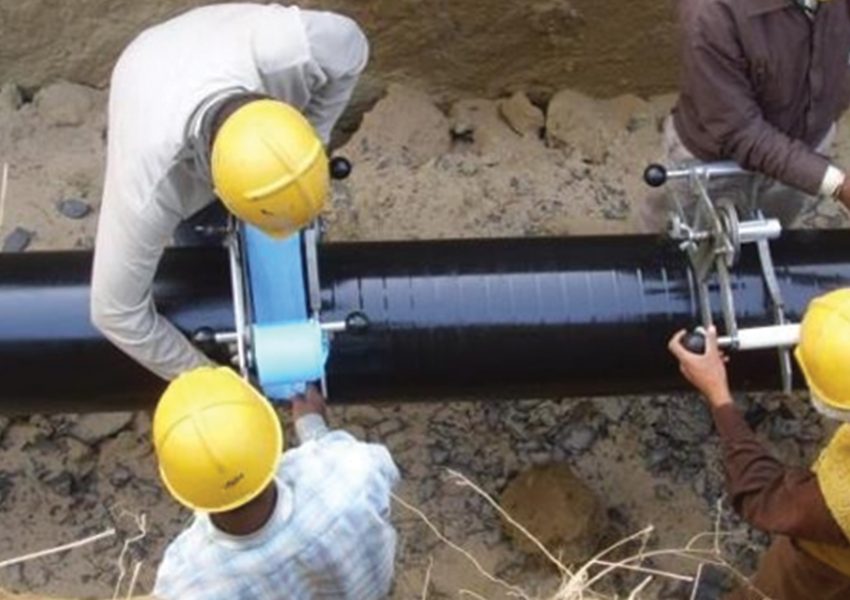

Pipeline Coating Rehabilitation

Oil India Limited is the oldest Oil & Gas company in India. Seal For Life has provided Polyken tape systems for their rehabilitation projects for many years. Most recently, Seal For Life secured orders for coating of 680,000 m2 of bare pipe surface area with Polyken’s cold applied tape system.

Features & Benefits

- Coating systems are in accordance with NACE, AWWA & ISO standards

- Corrosion prevention for new construction, rehabilitation in the oil, gas and water pipelines

- Meet the demands for mainline coatings, field joint coatings, & coating of special sections

- Manufactured in multiple plants for international business

- Fully supported global Technical Service team

Protecting the future

Protecting the future

Protecting the future

>0years

of being a Worldwide recognized cold tape coating manufacturer

+0

countries Polyken products are actively sold in, a true global presence

0°C

Unique high temperature cold applied tape technology up to 85°C (185°F)

Making an impact

60+Yrs

Main Results

Polyken systems have been utilized to protect pipelines against corrosion under various service conditions and environments around the world.