Heat shrinkable technology

Covalence

The original Heat-shrinkable Technology,

we invented it in 1957

About Covalence

Heat-shrinkable multi-layer sleeves that have high electrical resistance and low permeability.

Product line

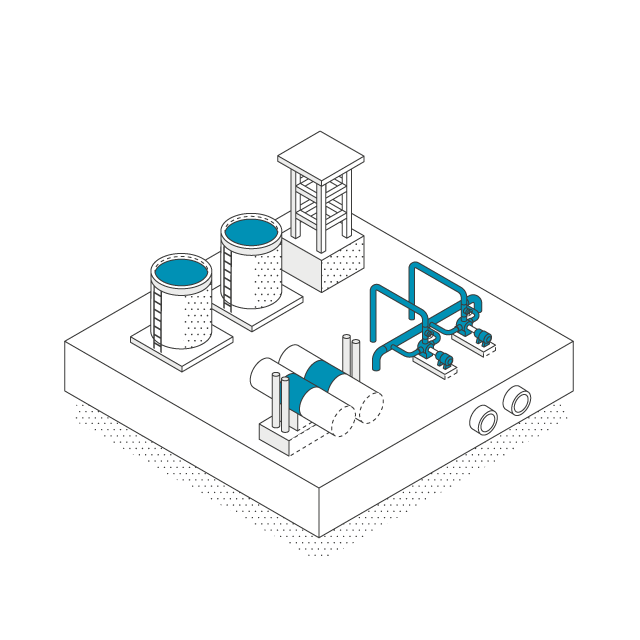

A series of 2- and 3-layer heat-shrinkable sleeves for applications including pipeline field joint corrosion prevention, mechanical protection, and sealing of district heating and district cooling pipelines.

Corrosion prevention

An irradiation cross-linked & stretched polyolefin backing with an adhesive laminated on in order to form the basic product. The adhesive may be either visco-elastic based mastic or co-polymer hot melt adhesives to match up with in-service performance requirements.

Features & Benefits

- Irradiation Cross-linked polyethylene and polypropylene backings

- Adhesives formulated for maximum corrosion prevention at low, ambient and high pipeline operating temperatures

- 100% solids epoxy primers for 3-layer systems utilizing "wet-system" application technology

- Products tailored for specific applications from large diameter water pipelines to high temperature oil & gas pipelines

- Global sales and technical support teams

Protecting the future

Protecting the future

Protecting the future

State-of-the-art performance

Approval by testing agencies around the world guarantees suitability for individual applications and field conditions.

The Covalence® DIRAX system is a patented three-layer formulation designed specially for HDD installations. The heat shrink sleeves meet all relevant global standards (ISO, EN, AWWA, NACE, GOST) ensuring suitability for pipeline applications and special field conditions.

>0years

as Heat Shrink Sleeve solutions leader

>0

heat shrink sleeve products suitable for applications in any pipeline market

>0

in-house R&D scientists, engineers and technicians actively developing products

40+Yrs

Main Results

Proven in-service performance

With technology born of the atomic age, shrink sleeves are unique in their ability to perform safely and efficiently. Easy-to-understand installation instructions are shipped with every product and clear product labeling allows rapid on-site identification.