Innovating thermal and sound protection

Mascoat

Combining superior technology, application history, and extensive testing

Visit WebsiteAbout Mascoat

Tested to the highest standards and are proven to conserve energy, protect personnel and prevent corrosion under insulation.

since 1995

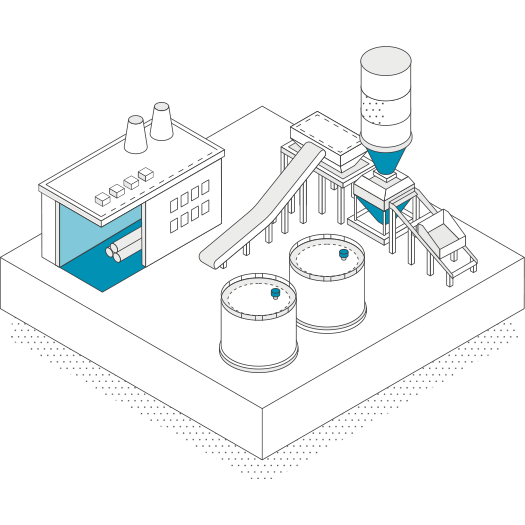

Mascoat manufactures the best coatings available for thermal insulation, condensation protection and sound control. Unique, environmentally friendly coatings not only provide proven performance but also reliably protect surfaces to completely prevent or greatly reduce long-term maintenance concerns.

Product line

Mascoat serves a wide variety of industries with coatings designed for unique needs in these areas; commercial, industrial, marine, automotive and others.

Features & Benefits

- Saves total installation time when compared to conventional insulation, anti-condensation, and damping methods

- Easy to install with no cutting, tapping, or special hangers; No special fabrication needed

- The coatings adhere to virtually any substrate and eliminate the potential for surface corrosion or corrosion under insulation (CUI)

- Long application life (25+ years) reduces year-over-year maintenance and associated costs

- Coatings are non-combustible and non-flammable

- 1-part, water-based coating have no "pot life" and contain no harmful chlorides

- If needed, the coatings can be applied to working substrates

- Superior technical and specification abilities by in-house experts

Protecting the future

Protecting the future

Protecting the future

Thermal insulating coating

Multi-purpose coating, providing insulation, protecting substrates and personnel, and preventing corrosion under insulation issues.

Mascoat Industrial-DTI thermal insulating coating works not only to reduce temperatures but also provides energy savings, thermal insulation, and personnel protection all in an easy spray-on application.

Global Industry leading experience

Mascoat

Our success in numbers

>0years

as the insulating coatings leader

0%

of damping and insulating coatings made in house

+0

million square feet of coating applied since 1995

Making an impact

20+yrs

Main Results

Marine thermal barrier coating

Formulated to meet the challenging, harsh marine environments and unique insulation requirements of the maritime industry. Mascoat marine products are currently used on thousands of vessels around the globe – from barges and workboats to luxury yachts and military craft.